8 May 2019

Optimizing workflow for greater productivity in the dental lab

Lab consolidation has created an intensely competitive environment, making it more critical than ever to maximize two key components of a successful lab: speed and quality.

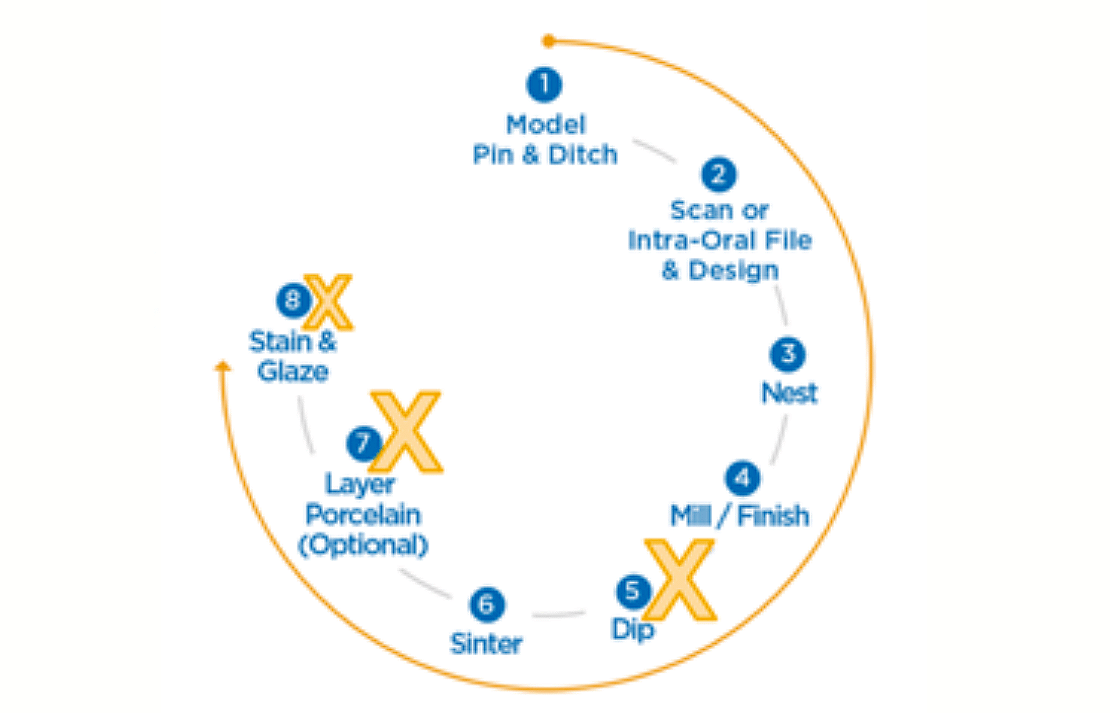

The Cercon xt ML “Glaze and Go” workflow:

Cercon xt ML provides additional workflow optimization advantages, including speed sintering capability in less than three hours, QR code scanning for easy use in the inLab MC X5 (with CAM software version 19 and later), and a keyway on the disc surface for exact positioning when using the same discs for multiple millings.

In summary, the restorative materials you choose have a big influence on the efficiency, productivity, and throughput of each case, so it’s important to carefully consider the working properties of each material you use in your lab, and select only those that produce high quality outcomes at a pace and workflow that keep your business successful.

For more information about Cercon xt ML and the entire line of Cercon materials click here.